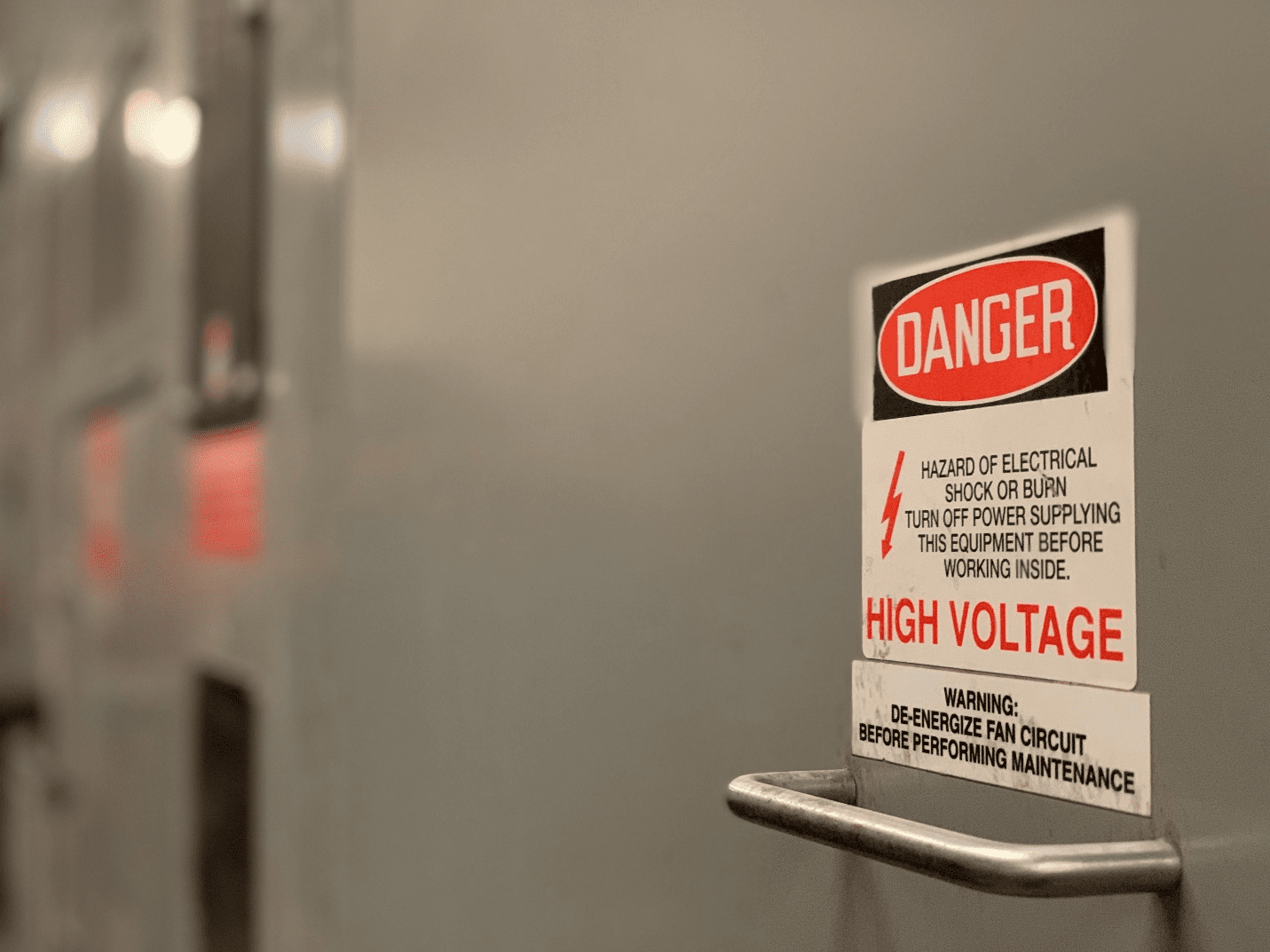

The production processes at a global continuous-process manufacturer uses a large number of heavy equipment. Any equipment in operation generates substantial kinetic energy in their hydraulic or electrical or mechanical systems. These equipment often need to be maintained during either schedule shutdowns or breakdowns. If adequate measures are not taken to release or cut-off this energy it may lead to major or even fatal injuries. It is therefore mandatory to take certain safety measures and follow equipment specific proper shutdown or breakdown maintenance procedures.

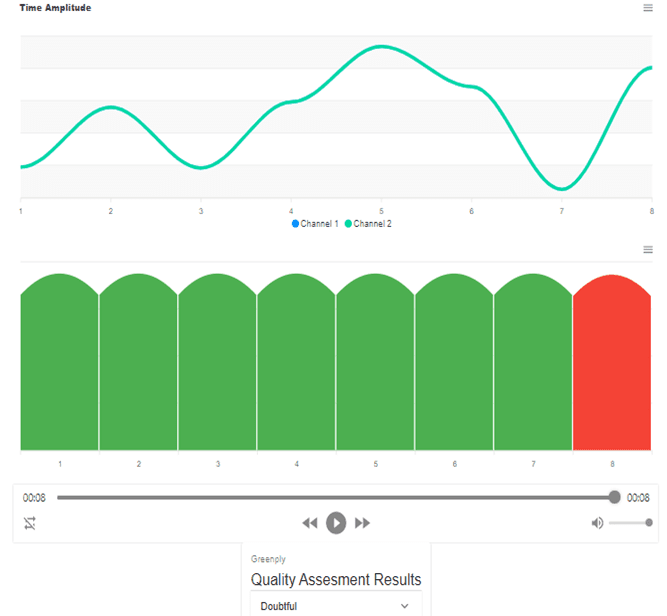

Alumnus helped the customer to build a new, web-based, standardised Lock-out Tag-out (LOTO) application to address their health and safety concerns. The new application caters to the need of all manufacturing units across the world and supports more than 14 languages to create, manage and generate procedures (SOPs). It can also generate PDF version of the SOPs in local languages and in English.

The application provides multistage approval processes following right routing to right authority for the approval of SOPs. The application provides facilities to add new plants, extends translation services to support any new language and enable users to use copy existing processes as templates to quickly create new plant specific SOPs and provides migration services to include existing plant specific procedures in the new desired format.

Alumnus’ application is now rolled out for all manufacturing facilities of the company globally.

Technology Stack:

Angular 12, .NET 7, ASP .NET Web API, GRPC, SQL Server with Graph