Quality Assurance of finished plywood boards at a client’s factory is carried out by a semi-skilled worker physically striking every finished ply at multiple places with wooden hammers. The worker then listens manually to the sound produced to assess the quality of the plywood as Acceptable or Defective quality. Each ply takes on average 2-3 expert labourers which hinders smooth flow of finished goods, costs more for scarce semi-skilled labour, particularly in a post-Covid scenario.

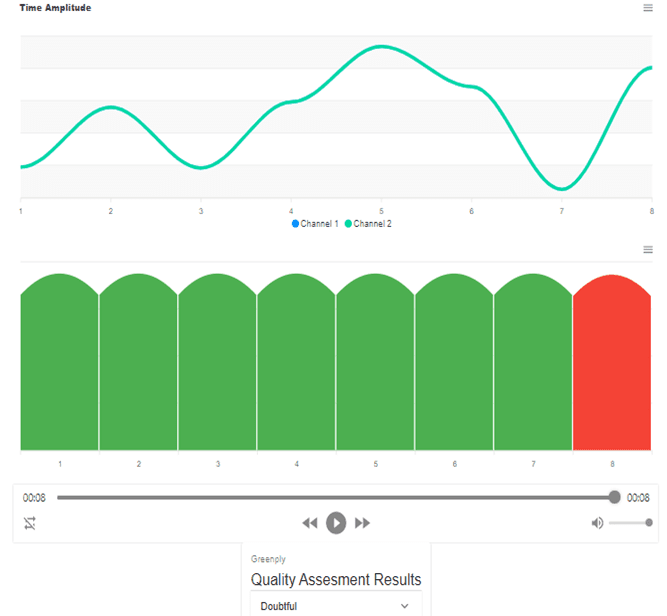

Alumnus proposes a SmartHammer solution which uses electronics built into the Hammer to ‘listen’ to the hammering sound. AI software then automatically judges the plywood as Acceptable or Defective.

A technology-enabled QA solution, this will achieve similar (or lower) cycle time with reduced manual involvement and improved productivity.

Technology Stack:

Digital Signal Processing (DSP), Raspberry Pi, Python, GNU octave, Arduino Nano, React and JavaScript, Python Flask